The new 2.4 million t/a plant of Wuyang Coal Mine was completed and put into operation in January 2008, and the process of coal processing adopts heavy media cyclone + TSS separator + flotation. Filter press is an important part of the coal slurry water treatment system, whether the operation is normal constraints on the production of the coal preparation plant, 2.4 million t / a new plant was built than the old plant's production capacity has been greatly improved, the filter press was selected 300 / 1500 × 2000, a U / X fast-opening filter press two. The machine is a fast-opening high-pressure diaphragm filter press, the use of electromechanical-hydraulic integration design and manufacture, a high degree of automation, to achieve automatic pressure, pressure, make-up pressure, feeding, pressing, blowing, loosening, stopping the push up three times to pull the plate to unload the plate, close the plate, stopping the push down, and other processes, to further reduce the water content of the cake to increase the processing capacity.

1Working Principle of Quick Opening Filter Press

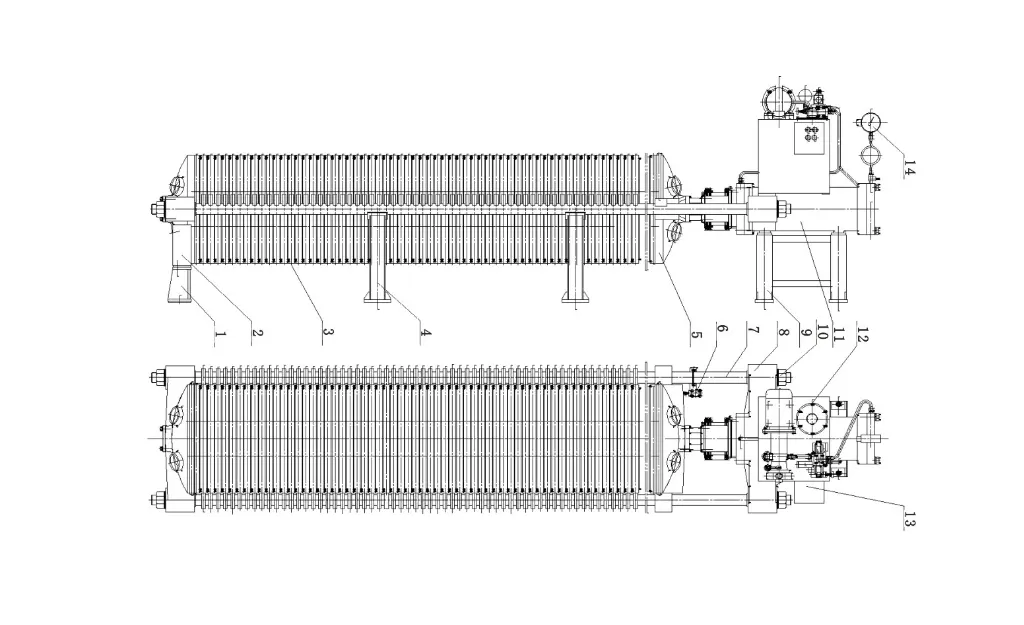

1.1 The composition of the fast-opening filter press fast-opening filter press by the frame, the main beam, filter plate, thrust plate, spacer plate, compression plate, seat, cylinder body, unloading mechanism, hydraulic station, electrical control components.

1.2 Working principle of quick-opening filter press The filter plate of quick-opening filter press consists of diaphragm plate and compartment plate, the piston rod on the cylinder body pushes the compression plate, and the diaphragm plate and compartment plate and filter cloth located between the compression plate and thrust plate are pressed to ensure that there is a pressure of slurry in the filter chamber for pressurised filtration, due to the diaphragm plate, the compressed air can be passed through the air intake port of the diaphragm plate to squeeze the filter cake and further reduce the water content of the filter cake. Due to the diaphragm plate, compressed air can be fed into the air inlet of the diaphragm plate to press the filter cake to further reduce the water content of the filter cake, and high-pressure air can also be fed into the inlet at the end of the thrust plate to carry out the intermediate air penetration through the layer of the filtering cloth to blow out the intermediate mud. There is also a part of the host to complete the power device of the pressure and release, under the action of the electronic control cabinet system, through the oil cylinder, oil pump, and hydraulic components to complete part of the system, when the system is pressed to seal the various chambers for filtration, and vice versa, loosened for unloading. The unloading part mainly consists of two gear motors and transmission shafts, sprockets, chains and other main parts, working under the action of electrical system. When the compression plate is loosened, the stop push a 1-move, the motor at the position of the support seat starts, pulling the cylinder seat and the compression plate through the chain to pull open the first part of the filter plate, the motor at the position of the stop push plate starts to drive the spacer to pull open the second part of the filter plate through the signal transmission in the electric control cabinet to make it reverse, driving the spacer to pull open the remaining filter plate so that the discharging process is completed. The machine has two working modes, automatic and manual, in automatic mode, the whole action process of the filter press will run in sequence according to the design procedure without manual intervention, and its running process is as follows: firstly, close the air switch, set the selector switch in the automatic position, press the procedure button, the pump station motor starts to start, and at the same time, release the electromagnetism valve is charged, and the pressing plate backs up, and touches the limit proximity switch to press the plate and stops automatically. Backward, at the same time stop push electromagnetic broad charged, stop push push move, contact with upward limit switch upward stop, at the same time the pump station motor stops running, pull the plate motor (stop push plate position) to start, drive the cylinder seat to move (once pull the plate unloading) to the limit switch motor stops, at the same time the pull the plate motor (stop push the plate position) start to drive the spacer plate to move (second pull the plate unloading) to the limit of the proximity switch, the motor reversed, drive the The partition plate moves in the opposite direction (three times pull the plate unloading) to the limit close to the switch motor stops, while pulling the plate motor (stop pushing the plate position) to start driving the cylinder seat to move (close the plate) to the limit close to the switch after the motor stops, at the same time, the pump motor to start the pumping solenoid valve is charged to stop the push push to move down, after contacting the limit switch stop pushing the solenoid valve is deenergised, at the same time, the pressure solenoid valve is charged to carry out the compression action to reach the upper limit of the pressure to the upper limit of the switch to the After reaching the upper pressure limit, it will turn into the pressure-keeping state, and the pump station motor will stop and start feeding, so that a working cycle will be completed. In manual mode, each action of the filter press is completed by manually operating each button, this mode is mainly used for debugging equipment, in addition, in the process of unloading, manual assistance is required or other circumstances, the unloading can be interrupted through the pause device, after the manual clearing is completed, the pulling of the plate to continue.

2 Failure analysis through the use of the filter press more than a year of the problems that occur, the analysis of the failure of three categories:

①Electrical faults: the main limit close to open the fault, solenoid valve failure, relay failure, electric contact pressure gauge failure and so on.

② mechanical failures: broken filter plate filter cloth, valve damage, damage to the climbing chain, pull the plate mechanism and other failures.

③ Hydraulic system failure: mainly hydraulic valve damage or clogging.

3 Troubleshooting methods

3.1 Electrical faults

1) in the operation of the programme to a certain procedure does not act, for example: stop push push down overtime compression is not carried out, first of all, to check the stop push down to move in place close to the switch whether there is a problem, such as the problem of replacing the close to the switch that is meh, if the up to move in place close to the switch is not extinguished, but also lead to the down to move overtime replacement of the close to the switch can be.

2) Pump station solenoid valve failure, resulting in not pressing or not loosening. Repeatedly stop the push pin does not move up or down, the treatment is to check whether the corresponding solenoid valve is electric or solenoid valve coil burned out, replacement can be.

3) electric contact pressure gauge failure, compression overtime or venting overtime is the electric contact contacts have problems, the treatment method is to adjust or replace.

4) the valve solenoid valve failure, such as a wind control valve should be opened when not open or closed when not closed, to check whether the valve solenoid valve coil is electrically charged, or whether the coil is burned out, the treatment method for the inspection of the line and relay or replacement of the coil, if it is the opening of the valve is open, it should not be open also open, it is possible that the solenoid valve line is connected to the electricity or the junction box into the water.

3.2 Machine-type failures

1) Leakage between the filter plate and the diaphragm filter plate, the reason is that there are sundries between the filter plate, the filter cloth is not flat and folded or the filter cloth is broken. Treatment: clean up the debris, organise and replace the filter cloth.

2) Filter plate rupture, the reason is that the broken filter cloth causes sandwich, the cake is not full of filter chamber before pressing, the filter plate inlet and outlet are blocked. Treatment: Replace the filter cloth in time, press the cake after filling the filter chamber, and clean the inlet and outlet ports.

3) The bearing of pulling plate shaft is damaged or broken, which will lead to the noise when pulling plate or pulling plate slanting, and should stop unloading in time. Treatment: replace the shaft and bearings, pulling the plate small chain broken will also lead to the filter plate tilt, should also stop discharging in time to replace the small chain.

4) Insufficient holding pressure due to worn piston seals and oil leakage in the oil circuit. Treatment: replace the seal to check the oil circuit.

5) The filtrate is not clear, the reason is that the filter cloth is worn, the filter cloth is not properly selected, the filter cloth stitching is open. Treatment: Replace the filter cloth.

3.3 Failure of the hydraulic system

1) insufficient holding pressure, the reason is that the liquid-controlled check valve out of control, treatment: replace the cleaning liquid-controlled check valve.

2) insufficient oil pressure, the reason is the relief valve is bad, oil level is insufficient, oil pump wear, bad valve or joint leakage, cylinder seal wear valve leakage, treatment: repair or replace the relief valve, refuelling, replacement of the oil pump, tighten the joints, replacement of the O ring or replacement of the seal.

3) hydraulic system noise, the reason is that the cylinder sucks in air, loose fasteners, hydraulic oil viscosity, treatment: open the bleeder valve bleed, will be loose fasteners fastened, replace the hydraulic oil.

4 Conclusion through the fast-opening pressure filter running more than a year to do an in-depth understanding of the common failures of the analysis, put forward a reasonable method of treatment, in the daily use and maintenance as long as a good grasp of the principle of conscientious operation will be able to improve the stability of the filter press, so as to better safeguard the normal production of the coal washing plant.

Filter press technical support: 18851718517

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses