Lithium has a low melting point, high boiling point, most negative potential, light mass, etc.,It is widely used in new energy vehicles, nuclear industry, aviation, medical, and other fields. Lithium is the most important basic raw material for new energy industry.,be known as "21New Energy for the Century". In order to accelerate the realisation of the strategic goal of "Carbon Neutral, Carbon Peak".,China has vigorously developed the lithium new energy industry,Demand for lithium feedstock is increasing year on year,Lithium's growing strategic position,A new round of competition for mineral resources has been launched[. Currently,The main sources of domestic lithium resources are salt lake lithium and ore lithium. Ore lithium mainly includes lithium pyroxene, lithium mica, lithium feldspar, lithium iron mica, lithium muscovite, lithium aluminium phosphorite, etc.. To ensure stable market supply of lithium raw materials,Lithium extraction from lithium mica,Has become an important way to obtain lithium feedstock,Yichun area in Jiangxi has the world's largest associated lithium mica mine[12]. During the beneficiation of lithium mica,Belt filters are commonly used in the dewatering of lithium mica concentrates.,Concentrate moisture is generally greater than18%,There are features such as high moisture of lithium mica concentrate, large equipment footprint and low processing efficiency. A mineral processing plant in Yichun area adopts a company's production ofFFPDewatering of lithium mica concentrate by horizontal quick opening filter presses,It has the characteristics of small equipment footprint, high processing efficiency and low moisture of lithium mica concentrate.,at the same time,It can reduce the transport cost of lithium mica concentrate and the drying cost of downstream lithium carbonate plant. This paper focuses onEffect of filter cloth type, cycle time, working pressure, type of filter aid, and dosage of filter aid in lithium mica concentrate on the moisture of lithium mica concentrate in a fast-opening filter press.

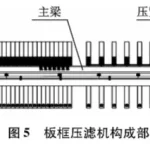

1The test specimens were taken from a lithium mica concentrate of a mineral processing plant in Yichun area.,The results of multi-element chemical analyses of this lithium mica concentrate and the results of sieve analyses of the lithium mica concentrate are shown in Table1wristwatches2The From the table1wristwatches2knowable,This lithium mica concentrateLi2Oquantity contained1.71%,Al2O3quantity contained29.34%,SiO2quantity contained47.60%. Lithium mica concentrate particle size<75μmContent as a percentage of32.79%,<25μmContent as a percentage of14.63%,The dewatering process is difficult and the concentrate moisture is high when using traditional belt filter dewatering.2FFPHorizontal quick-opening filter press introductionQuick-open horizontalFilter press is a high capacity filter press.,Mainly used for solid-liquid separation.FFPQuick-opening horizontal filter press is shown in the figure.1Shown. Operating time,The main steps are as follows.

1)infeed:The material is pumped to each filter chamber of the filter press.,Until it's completely full.

2)filtration:Rising feed pressure,Cake formation on the surface of the filter cloth,The filtrate is discharged through a collection channel.

3)squeezes:Diaphragm after extruded media enters each chamber,The diaphragm squeezes the cake between the filter cloths.,Force the filtrate through the filter cloth.

4)air dryness:Compressed air passes through the filtrate channel on the diaphragm side,Blow-dry the moisture in the filter cake to a minimum. During the drying process,The filter cake keeps the diaphragm squeezed,The filter cake can be maintained without cracking.

5)Pipe flushing, blowing:Residual slurry and water in the pipeline is cleaned and disposed of.

6)Diaphragm Release:The compressed air in the diaphragm is completely released.

7)pancake unloading:approximate30sshort time,All the filter cake is discharged at once. When the filter plate set is fully opened,The filter cloth is vibrated to ensure complete cake discharge.

8)Filter cloth rinsing:After unloading the cake,The filter cloth is flushed by a shower pipe mounted on top of the filter plate set. This ensures the removal of residual filter cake from the surface of the filter cloth.,and ensure good running conditions for the next cycle.Quick-open horizontalFilter presses have the following advantages:

1)High efficiency of equipment operation,Short technical time for opening and closing plates, etc.(<30s).

2)Weighing system installed,Measurement of the feed volume at any time,and automatically adjusts operating parameters;

3)Filter plates in accordance with European quality standards,Reliable quality, removable and replaceable edge wear parts,No need to replace the entire filter plate;

4)Automatic vibration of the filter cloth after discharging the cake,Helps to unload the cake and remove residual cake crumbs,Completely eliminates the need for manually assisted unloading,Avoid residue being trapped between the filter plates,Causes deformation of slurry or filter plates;

5)High degree of automation,the scene (of the incident)PLCcompatibility withDCSsystem connection,Observation of equipment operation status and remote start/stop can be realised in the central control room.;

6)Low running costs,Fully automatic operation of the whole plant,The site is largely unmanned,It can save more labour cost for customers.

3Results and Discussion A lithium mica concentrate from a beneficiation plant in the Yichun area was used as the object of study.,Lithium mica concentrate particle size<75μmquantity contained32.79%,Slurry concentration55%. Slurry concentration determines filter press feed time,When the slurry concentration is constant,The feed time is unchanged.

3.1Filter Press Cloth Type Condition Test Filter cloth is quite a key component in the filter press equipment.,Because of the different substances filtered by the industry,Relatively different requirements for filter cloth,This results in many types of filter cloths. In this paper, a suitable filter cloth for dewatering lithium mica concentrates is identified through industrial tests in the field.,existFFPHorizontal quick release filter press cycle time900s (Of which feed time180s.squeeze time330s.drying time360s)Work stress1MPaconstant time,To investigate the effect of different filter cloth types on the moisture of lithium mica concentrate. The test results are shown in Table3drawing2. From the table3drawing2knowable,Air permeability using nylon monofilaments300L/(m2)-min)of filter cloth lithium mica concentrate with the lowest moisture content,because of15.89%,And it was found in the test that nylon monofilament filter cloth has better peeling performance,Rapid cake stripping,The main reason for this is the high filtration accuracy and precision of nylon monofilament filter cloths.,It can filter out data with a diameter of1μmmicroparticles,This will help to prolong the use cycle of the filter cloth and improve the efficiency of the filter press.

3.2Filter press cycle time condition test Horizontal quick-opening filter press with nylon monofilament air permeability300L/(m2)-min)Filter cloth, working pressure1MPaconstant time,The effect of filter press cycle time on the moisture of lithium mica concentrate was investigated. The test results are shown in Table4drawing3. From the table4drawing3knowable,As the slurry concentration is more consistent,Then the feed and filtration times are the same,With the increase of extrusion time, drying time,Lithium mica concentrate moisture is reduced. When the total cycle time exceeds930ssurname Shi,Lithium mica concentrate moisture reduction is not significant. Taken together,Select cycle time930sOperating parameters as a filter press,At this time, the moisture of lithium mica concentrate is15.32%.

3.3Test of working pressure conditions of quick-opening filter pressesFFPHorizontal quick-open filter press with nylon monofilament air permeability300L/(m2)-min)Filter cloth, cycle time930s (where extrusion time345s.drying time375s)constant time,To investigate the effect of filter press working pressure on the moisture of lithium mica concentrate. The test results are shown in Table5drawing4. From the table5drawing4knowable,With the increased pressure of work,Lithium mica concentrate moisture reduction. When the working pressure of the filter press exceeds1.1MPasurname Shi,Slow reduction in concentrate moisture,a round-up,Determining work pressure1.1MPaOperating parameters as a filter press,At this time, the moisture of lithium mica concentrate is15%.

3.4Lithium mica concentrate filter aid type condition testcetestntrateFFPHorizontal quick-opening filter press filter cloth type, cycle time, working pressure and other equipment parameters to determine the,To investigate the effect of filter aid type and filter aid dosage on the moisture of lithium mica concentrate. The effect of filter aid type on the moisture of lithium mica concentrate was investigated first. The inorganic filter aid polymeric aluminium chloride, organic filter aid840Organic filter aids320Filter aid comparison tests were conducted. At the same dosage500g/tpresent situation,To investigate the effect of filter aid type on the moisture of lithium mica concentrate. The test results are shown in Fig.5. By Chart5knowable,At the same dosage500g/tpresent situation,When making polymerised aluminium chloride,Lithium mica concentrate moisture13expense or outlay.79%Filtering effect of polymerised aluminium chloride. Filtering aid effect polymerised aluminium chloride>organic filter aid320>organic filter aid840,This is due to the fact that the molecular chains of polymeric aluminium chloride are fixed on the surface of different fine or very fine particles.,Aggregates formed by the formation of polymer bridges between individual fine or very fine particles,Aggregates do not cause clogging of the filter pores of the filter cloth during filtration.,At the same time the stripping of the filter cake is better,The filter cloth has a longer life cycle.

3.5Lithium mica concentrate filter aid dosage condition testFFPAir permeability of nylon monofilaments used in horizontal quick-opening filter presses300L/(m2)-min)Filter cloth, cycle time930sWork stress1.1MPaPolymeric aluminium chloride for filter aids,To investigate the effect of polymeric aluminium chloride dosage on the moisture of lithium mica concentrate. The test results are shown in Table6drawing6The From the table6drawing6knowable,With the increased use of polymeric aluminium chloride,Reduced moisture in lithium mica concentrate. At polymeric aluminium chloride dosages greater than450g/tsurname Shi,Smaller rate of moisture reduction in lithium mica concentrate,Consideration of costs, etc.,Selection of polymeric aluminium chloride dosage450g/t,At this time lithium mica concentrate moisture13.80%.3.6FFPComparative analysis of horizontal quick opening filter press and traditional belt filter according to lithium mica concentrate743.75t/h (dry tonne)Selection Calculation,FFPComparative analysis of horizontal quick-opening filter press and traditional belt filter is shown in the table.7. From the table7knowable,FFPHorizontal quick-opening filter press has the features of small equipment footprint, high dewatering efficiency, high degree of automation and saving transport costs.

4reach a verdict

1)A lithium mica concentrate from a beneficiation plant in Yichun area as a research object,This is achieved through a review of theFFPStudy on the type of filter cloth, cycle time, working pressure, type of filter aid and dosage of filter aid for lithium mica concentrate in horizontal quick-opening filter presses,The results of the tests show thatFFPAir permeability of nylon monofilaments used in horizontal quick-opening filter presses300L/(m2)-min)Filter cloth, cycle time930sWork stress1.1MPaPolymeric aluminium chloride for filter aids450g/tsurname Shi,The lithium mica concentrate has a moisture of13.80%.

2)Lithium mica concentrate in filter aid condition test,Polymeric aluminium chloride is the most effective in reducing the water content of lithium mica concentrates,Filtering effect polymeric aluminium chloride>organic filter aid320>organic filter aid840This is due to the fact that the molecular chains of polymeric aluminium chloride are fixed on the surface of different fine or very fine particles. This is due to the fact that the molecular chains of polymeric aluminium chloride are fixed on the surface of different fine or very fine particles.,Aggregates formed by the formation of polymer bridges between individual fine or very fine particles,Aggregates do not cause clogging of the filter pores of the filter cloth during filtration.,At the same time the stripping of the filter cake is better,The filter cloth has a longer life cycle.3)Compared to belt filters,A mineral processing plant in the Yichun area usesFFPHorizontal fast-opening filter press has the characteristics of small equipment footprint, high dewatering efficiency, high degree of automation, saving transport costs and so on.,Solved the industry problem of high moisture in lithium mica concentrate in Yichun area.,It is the first time to be successfully applied in large scale in the lithium mica beneficiation industry.,Very important demonstration significance in the industry,Future applications are promising.

Author: Guo greatness,Chen Yifeng (1901-1981), Mao Zedong's first wife,Xie 添,Tang Lijing (1897-1987), translator and editor of the Ming dynasty

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses