1 Overview Guangzhou Paper Group is a large state-owned backbone enterprise integrating pulping, papermaking, thermoelectricity and environmental protection, with three newsprint production lines and one whiteboard production line, and a 30,000t/d and a 150,000t/d wastewater treatment system. As the whole waste paper is used for deinking pulping, the short fibre lost in the pulping process and the dust, ink and other materials in the waste paper are discharged into the rear sewage treatment system along with the production wastewater in the process of production, so a large amount of sewage sludge is generated. The traditional process generally adopts double-net filter press to dewater the sludge by gravity and then landfill or compost it. However, due to the low dewatering efficiency of the double-net filter press, the water content of the treated sludge still reaches about 75%, so the sludge is huge in volume, which needs to take up a large amount of land for landfill, and generates a large amount of transportation and treatment costs and is easy to cause secondary pollution. As the national environmental protection requirements become stricter and stricter and the land resources decrease, the supervision of solid waste is getting stronger and stronger, and it must be handled by qualified professional units and supervised throughout the whole process, so the treatment cost increases greatly. In order to develop in the long run, the company makes use of the opportunity of retreating from the second to the third, environmental protection relocation to build a plate and frame filter press to carry out deep dewatering treatment for the sludge of the sewage treatment system, and supporting the construction of a comprehensive utilization of waste residue power plant, specializing in incineration of deep dewatering treatment of sewage sludge, so as to achieve the purpose of harmless treatment and recycling of resources (Note: the company's sewage sludge contains a certain amount of fibre and ink, and after deep dewatering, it still contains a certain amount of heat). (Note: Our sewage sludge contains a certain amount of fibre and ink, which can be recycled after deep dewatering and still contains a certain amount of heat).

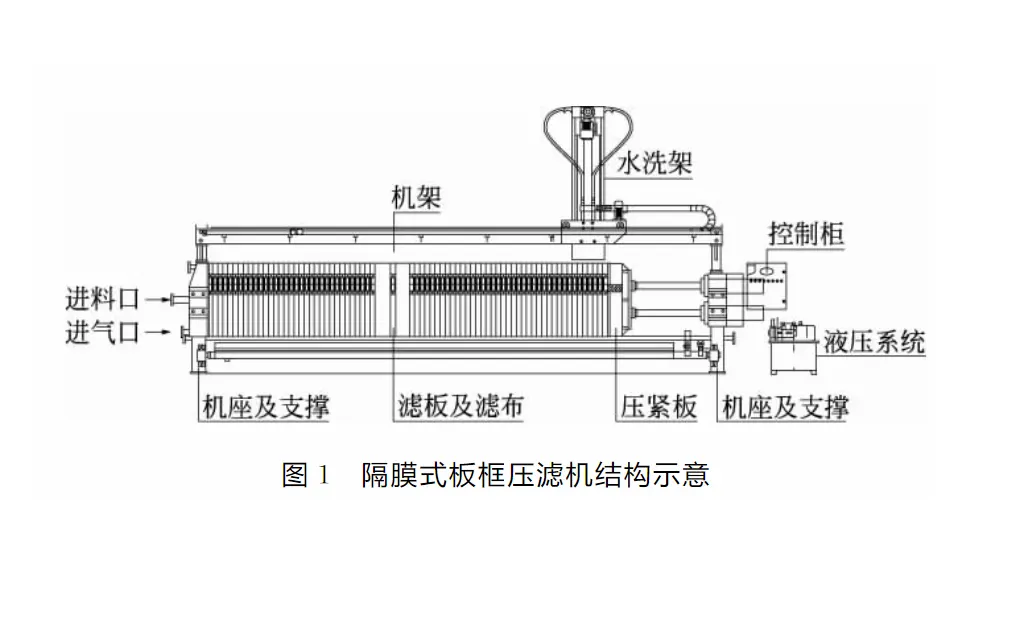

2 Working Principle of Diaphragm-type Plate and Frame Filter Press The sludge deep dewatering equipment adopted by the Guangzhou Paper Group is a fully automatic diaphragm-type plate and frame filter press. The automatic diaphragm filter press is a kind of intermittent pressurised filtration equipment, which can be used for solid-liquid separation of various suspensions. The principle of dewatering in this equipment is mainly through high pressure feeding and high pressure pressing. Under the effect of pressure, the water in the suspension in the filter chamber enters into the filtrate side through the filter cloth, while the solid particles are retained in the filter chamber under the interception of the filter cloth, thus realising the purpose of solid-liquid separation. Plate and frame filter presses are equipped with two types of filter plates: diaphragm plates and frame plates, which are arranged at intervals. The diaphragm plates are hollow and have a certain degree of expansion, while the frame plates are solid hard plates that act as a top press. When the press liquor is injected into the inner chamber of the diaphragm plate, the diaphragm plate gradually expands under the pressure, and the volume of the filter chamber becomes smaller and smaller, thus further squeezing out the sludge water in the filter chamber. The operation of the filter press is intermittent feeding, with one cycle consisting of feeding, pressing, draining and discharging. The moisture content of sludge treated by diaphragm-type plate and frame filter press can generally reach below 50%, and its dryness is related to the high pressure feed pressure and press pressure, but considering the economy of operation and safety of equipment, the design selects the high pressure feed pressure and press pressure to be 1.6MPa, and the dryness of sludge to be 50%~60%.

3 System design and operation and maintenance The wastewater treatment system of GZG is a tertiary treatment process, and the process flow is as follows: physical sedimentation, (Ic anaerobic + SBR aerobic) biochemical treatment, and shallow air flotation, so the sludge produced by the system is not only physical sludge produced by sedimentation, but also residual sludge produced by the biochemical treatment of the SBR and air flotation sludge. The process of the sludge treatment system is as follows: the physical sludge from the sedimentation tank and the residual biochemical sludge from the SBR enter the sludge thickening tank for thickening, and then sent to the filter press for treatment. The air-float sludge, which is combined with a large number of small bubbles and has a low specific gravity, is difficult to be thickened by gravity settling, so it goes directly to the sludge conditioning tank. The thickening tank is buffered and can be processed intermittently, but the air flotation sludge is produced continuously and sent to the sludge conditioning tank due to its continuous operation.The sludge concentration in the conditioning tank will fluctuate, and the flocculation effect of the chemicals will also fluctuate. Since the plate and frame filter press is fed intermittently, the sludge treatment capacity will change with the change of operation status, so the sludge concentration in the conditioning tank will fluctuate, and the flocculation effect of chemicals will also fluctuate, which will interfere with the normal operation of the filter press. In response to these problems, we focused on optimisation in the system design.

3.1 Increase the pre-dewatering facilities The previous design of plate and frame filter press dewatering system is that all kinds of sludge enter the sludge conditioning tank to be mixed and dosed with chemicals, and then fed into the plate and frame filter press by feed pumps for filter dewatering. The consistency of the feed depends on the mixing consistency of the various sludges entering the conditioning tank. The air-float sludge is difficult to thicken by the conventional gravity thickening method due to the low specific gravity of the air bubbles carried by the air-float sludge, so the system is generally designed to send the air-float sludge directly to the sludge mixing tank for dewatering. Due to the low concentration of the air-float sludge and the looseness of the sludge because of the fine air bubbles, the concentration of the mixed sludge will be low and the dewatering effect will be poor when the proportion of the air-float sludge is large, and it will easily be adsorbed on the surface of the filter cloth and block the filter channel of the filter cloth. In order to eliminate the influence of sludge concentration fluctuation on the operation, we designed a gravity bed for pre-dewatering before the sludge conditioning tank. The principle of gravity bed is: after flocculation, the suspended liquid enters the gravity bed, and under the effect of gravity, the external water of the material is discharged through the filter screen into the catch basin, while the concentrated material after preliminary dewatering stays on the filter screen, which is transported to the next process. The coagulated suspension is dewatered by the gravity bed, and the concentration is increased to 5-10%, and then fed into the plate and frame filter press system for treatment, which can greatly improve the efficiency of the plate and frame filter press. Figure 1 shows the flow chart of the newly designed sludge treatment system:

3.2 Optimisation of dosing system The design of plate and frame treatment system generally sets the dosing point in the sludge conditioning tank, i.e., the chemicals are directly added to the sludge conditioning tank to stir and flocculate. In order to ensure the flocculation effect and stable material quality, the system is generally designed with two conditioning tanks, but it needs to take up a lot of space, in addition, the operation and control requirements are higher. Due to the limitation of our site, it is difficult to arrange two sludge conditioning tanks, so we chose to use one conditioning tank in the system design and borrowed the original sludge mixing tank as the transfer tank. In order to eliminate the influence of fluctuating sludge composition on flocculation of chemicals, we adjusted the addition point of flocculant. After exploring and learning from the past operating experience, we adopted the pipe mixer for flocculation and set the dosing point on the pipe in the range of 3-5 m before entering the gravity bed. The flocculant and the material are mixed rapidly in the pipeline for (2-3) S, and the flocculating reaction is carried into the gravity bed. As the inlet of gravity bed is open, the flocculation effect of materials can be observed at any time, so the dosage of chemicals can be adjusted timely according to the flocculation effect of materials and changes in the composition to ensure good flocculation effect and to lay the foundation for normal dewatering of plate and frame filtration in the latter part of the process.

3.3 Selection of mixer form After the material is pre-dewatered by gravity bed, the concentration is greatly increased, and from the operation data, the concentration of mixed sludge is increased from 1.5% to 3% to 5% to 7% before dewatering, and the processing capacity of plate and frame machine is greatly increased. However, the fluidity of the material becomes worse after the concentration is increased, therefore, in order to ensure the material entering the plate and frame with uniform concentration and avoid the floc being dispersed again due to the excessive stirring, the mantle speed mixer is equipped in the inlet tank of the plate and frame machine with the vertical installation and the rotating speed is selected to be (5-8)r/min, so as to make the high-concentration material enter into the filter-pressing system after stirring and homogenising smoothly.

3.4 System Operation and Maintenance The plate and frame filter press adopts polypropylene monofilament woven wire mesh as the filter bag, and there is a gap between the wire mesh of the mesh mesh mesh. When the material is squeezed under high pressure, the liquid in the material enters into the filtrate area through the gap between the wire mesh mesh, and the sludge is retained in the mesh bag. In order to facilitate the collection of filtrate, the surface of the frame plate is designed with a raised nail point, and the filtrate is collected through the concave channel between the nail points and discharged into the main collecting pipe. However, due to the high operating pressure, the fine particles in the material will partially penetrate the filter cloth into the filtrate side and deposit in the concave channel of the frame plate, and the concave channel will be blocked by the accumulated particles, and the concave and convex points will disappear, resulting in poor drainage of the frame plate, which will have a certain impact on the filtration efficiency of the filter cloth. Although the plate and frame machine is equipped with an online cleaning machine, the cleaning machine cannot clean the mud on the filter plate, so it is necessary to regularly clean the filter cloth and frame plate offline. The method of cleaning is to stop the filter press offline, remove the filter cloths, and use high-pressure water guns to wash the exposed filter plates one by one, so as to clean off the sludge deposited in the concave channels and restore the hydrophobic channels of the frame plates. Similarly, the filter cloth is washed on both sides with a high-pressure water jet. If the filter cloth is scaled, it can be soaked in citric acid and then rinsed with high pressure water to restore the filtering capacity of the cloth. The general cleaning cycle is four months. Because the filter cloth is a consumable product, the general use cycle is 4 months, but after the use of off-line cleaning, the use cycle can be extended to 9 ~ 10 months, greatly reducing the operating costs.

4 Conclusion The diaphragm plate and frame filter press system, through reasonable system design and effective operation and management, can give good play to the deep dewatering efficiency of the equipment, so that the dryness of sludge reaches more than 50%, which can be directly sent to the boiler for incineration, providing technical support for the reduction and harmless treatment of solid waste, and laying a solid foundation for the enterprise to achieve the goal of energy saving and environmental protection.

Author:Lai Hai Yun (1905-1995), Mao Zedong's second wife

Su Dong Technology: 18851718517

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses