As an important filtration equipment, filter press is widely used in various industries, such as chemical industry, metallurgy, environmental protection and so on. As an important industrial city in China, Nanjing has a certain scale and influence in the production of filter presses. This article will focus on "how much is the price of filter press in Nanjing?" This article will focus on the topic of "How much does the production of filter press cost in Nanjing?" and discuss the price situation in the Nanjing filter press market and the factors that affect the price.

I. Nanjing Filter Press Market Overview

Nanjing's filter press market after years of development, has formed a more complete industrial chain. From the supply of raw materials, parts processing to the assembly of the whole machine, Nanjing has a more complete industrial supporting capacity. This provides a solid foundation for the development of Nanjing filter press industry.

Second, Nanjing filter press price analysis

1. Price levels

The price level of filter presses manufactured in Nanjing varies depending on the model, specification, material and process. Generally speaking, the price of large-sized filter presses is higher, while the price of small-sized filter presses is relatively lower. The price of filter presses in Nanjing is competitive compared with other regions in China.

2. Price impact factors

(1) Models and specifications: The prices of different models and specifications of filter presses are different. Generally speaking, the price of large-size filter press is higher because its structure is more complex, and the required raw materials and manufacturing costs are also higher.

(2) Material: the material of the filter press also has a great influence on the price. High-quality materials can ensure the service life and stability of the filter press, but they also increase the manufacturing cost. Common materials include carbon steel, stainless steel and so on.

(3) Process: Different manufacturing processes also have an impact on the price of filter presses. Advanced manufacturing process can improve the performance and reliability of the filter press, but it also increases the manufacturing cost.

(4) Market supply and demand: Market supply and demand are also important factors affecting the price of filter presses. When market demand is greater than supply, the price of filter presses may rise; conversely, when supply is greater than demand, the price of filter presses may fall.

Third, Nanjing filter press market competition pattern

The filter press market in Nanjing is characterised by a certain degree of competition. The major suppliers in the filter press market in Nanjing include large industrial companies and a number of small and medium-sized producers. These companies compete for market share in terms of product quality, price and service. As technology continues to advance and the market continues to change, filter press companies in Nanjing also need to continuously improve their competitiveness to meet the challenges of the market.

Fourth, the future development trend of Nanjing filter press market

In the future, the filter press market in Nanjing still has a large space for development. On the one hand, with the continuous development of domestic industry, the demand for filter presses will continue to grow; on the other hand, the continuous progress of technology will also drive the filter press enterprises in Nanjing to continue to innovate and improve product performance and quality. The improvement of environmental protection requirements also provides new development opportunities for Nanjing's filter press enterprises. Therefore, it is expected that the filter press market in Nanjing will continue to maintain stable growth in the future.

V. How to choose the right filter press in Nanjing

For customers who need to buy a filter press, there are several factors to consider when choosing the right NJ filter press:

1. Performance parameters: It is necessary to choose the appropriate models and specifications according to the actual needs to ensure that they meet the requirements of the production process. At the same time, we should consider the filtration area, working pressure, filtration precision and other parameters of the equipment.

2. Material: Choosing high-quality materials can ensure the stability and service life of the equipment. For example, for applications in high-temperature environments, you need to choose high-temperature-resistant materials.

3. Manufacturing process: Advanced manufacturing process can ensure the precision and reliability of the equipment. Customers can choose filter presses with different processes according to their needs.

4. After-sales service: choosing a supplier with good after-sales service can ensure the maintenance and upkeep of the equipment during use. Customers should pay attention to the quality of the supplier's after-sales service.

5. Price: Under the premise of meeting the performance requirements, customers should choose products with good cost performance. At the same time to consider the long-term operating costs and maintenance costs of the equipment.

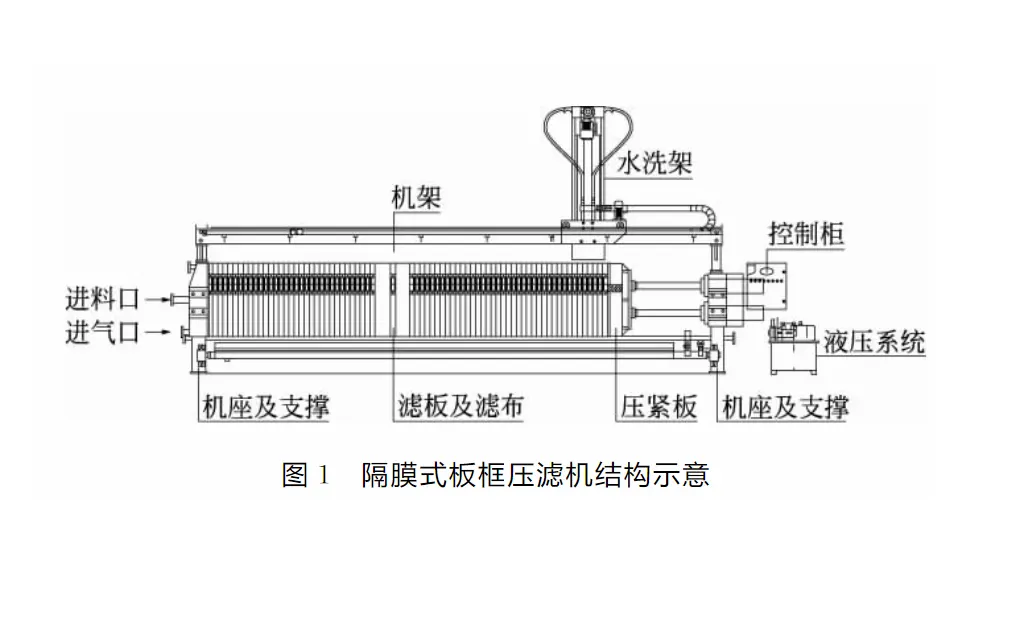

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses